So today is the day where all fyp's students been waiting for. We are going to do the fyp presentation in front of two assessors, Madam Johara and Madam Amalina, from the Electronic section. The presentation went smoothly. So here we would like to give our many thanks for those who helped us on this project and also to our supervisor who had been with us for one year to supervise us. Alhamdulillah we managed to do the presentation well.

Friday, 20 December 2013

Friday, 13 December 2013

WEEK 13 (Our Project)

Here is the video of our project.

Since

this project is important to monitor the waste management system, there is some

recommendations to improve this project are here by proposed. Some of the

suggestions for future development are listed as below :

1.

Use

RFID as tracking device.

RFID

is the wireless non-contact use of radio-frequency electromagnetic fields to

transfer data, for the purposes of automatically identifying and tracking tags

attached to the dustbin. This will prevent the dustbin from getting stolen and

able to track the dustbin if it is being move to somewhere else.

2.

Place

a LED advertisement board

It

can help the waste management service provider to generate income by offering

an advertisement such as nearest hotel promotion that can be display and seen

by the visitor and tourist.

3.

Use

WIFI instead of GSM

By

using WIFI, it can helps to reduce cost for credit top up and maintenance. By

using WIFI, it can provide smartphone applications that can be access by

public. By downloading the application, maybe the public can give feedback,

rating and recommendation that will benefit the waste management service

provider to increase their effectiveness.

Saturday, 7 December 2013

WEEK 12 (Report Preparation)

This week, we worked on the final report. We did chapter 1 and 2. We also summarized what we did on both chapters. Chapter 1 is where we cover the introduction, while chapter 2 we cover the literature review. However, we had a little problem with chapter 2. It was because there was no previous project of smart dustbin at our university. So what we did was we reviewed the smart dustbin on the internet, and also we made the literature review on GSM modem.

Friday, 29 November 2013

WEEK 11 (Poster & Pamplet)

The fyp exhibition is around the corner. It is nerve-wrecking for all students who are taking fyp this semester. So today, at 3pm, we had FYP briefing at TTL. This was the second briefing. The lecturer gave informations regarding FYP presentation and exhibition that will be held on the Engineering Day.

This week, we worked on the poster and pamplet. This were the requirements of fyp presentation.

These are the outlines for our poster and pamplet.

This week, we worked on the poster and pamplet. This were the requirements of fyp presentation.

These are the outlines for our poster and pamplet.

Poster

Outer Cover Pamplet

Inner Cover Pamplet

Friday, 22 November 2013

WEEK 10 (Finishing Product)

Most of all, we had finished the circuit but did not on the product. As for the dustbin, we borrowed the admin's small dustbin and as for the casing, we used cardboard to place the circuit on it.

This week we finalized the finishing product.

This week we finalized the finishing product.

Saturday, 16 November 2013

WEEK 9 (Project Result)

The

result of the tests performed between the connection of hardware, software and

operational range of the GSM module. The control panel circuit was connected

with the power supply, then the infrared sensor detect movement and produce a

long fall sound. When the dustbin is full the infrared sensor will detect and

send command to GSM modem through microcontroller. Then its result to receiving

alert that indicate the dustbin is full as shown in poster.

Saturday, 9 November 2013

WEEK 8 (Control Panel)

This we start work on our final report and also draw the circuit diagram for control panel circuit to be attach in final report at hardware development section.

Friday, 1 November 2013

WEEK 7 (Software Development)

For software development we have use the Microcode Studio software.

MicroCode Studio is a powerful, visual Integrated Development Environment (IDE) with In Circuit Debugging (ICD) capability designed specifically for microEngineering Labs PICBASIC PRO™ compiler. Compilation and assembler errors can easily be identified and corrected using the error results window. Just click on a compilation error and MicroCode Studio will automatically take you to the error line. MicroCode Studio even comes with a serial communications window, allowing to debug and view serial output from microcontroller.

The MicroCode Studio ICD communicates with the microcontroller using its

hardware USART. Refer the the Microchip

data sheet for the microcontroller used if unsure which pins the device uses

for its USART. For example, the PIC16F877A uses PORTC.7 for RX and PORTC.6 for

TX. The ICD will work with microcontrollers running at different clock

speeds. However, it is essential that your PBP code has the correct

oscillator setting defined. By default, this is 4MHz.

More extensive micro

coding has also been used to allow small and simple micro architecture to

emulate more powerful architecture with wider word length, more execution units

etc; a relatively simple way to achieve software compatibility between

different products in a processor family.

To develop program in the PIC, microcode

have been used to program the sensor so that it applicable of the chicken coop

environment. Actually microcode is easily to be used and understand for the

beginner programmer. It does not have to see the difficult term to write the

programmed.

Friday, 25 October 2013

WEEK 6 (Troubleshoot Circuit)

Hardware

testing involved a systematic approach to built interfacing circuit which is

beginning with testing the component and connection.After the connection is

functional, the full circuit is construct. However, there are a few problems

faced during the hardware development such as the speaker is not functioning

and the connection loss between control panel circuit and GSM modem that cause

the alert message was not delivered. . Then the circuit was troubleshoot by

changing the speaker and RS 232 cable with the new one and solder it to the

circuit as shown in figure below.

Saturday, 19 October 2013

WEEK 5 (Soldering)

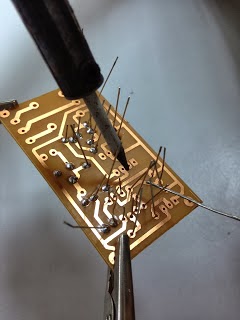

After we had done the PCB processes, we solder the component on the completed UV board. We also tested the components using multimeter.

We do the soldering in our supervisor's lab at level 2, the electronic section.

We do the soldering in our supervisor's lab at level 2, the electronic section.

Friday, 11 October 2013

Friday, 4 October 2013

WEEK 4 (PCB process)

This week, we were doing the cutting & etching process.Plus we also survey the price and components for this project. We have bought all the things needed to process with the next process that is soldering the circuit.

Cutting the UV board

UV board & outline circuit

Etching process

Friday, 27 September 2013

WEEK 3 (PCB outline)

Before we start doing the etching process, we did the circuit outline first. For the outline, we used DipTrace software.

These are the circuit outlines :

DipTrace software

These are the circuit outlines :

IR Sensor

Voice Recorder Module

Friday, 20 September 2013

WEEK 2 (Research & Components)

We did some research on The Deepest Bin. However, there were not many information on this project, but there was an example of smart dustbin on the youtube that was similar to our project. Here is the link of the smart dustbin >> http://www.youtube.com/watch?v=cbEKAwCoCKw

Back to our project, instead of making the dustbin as an attraction, we add on GSM technology to increse the efficiency of the waste management system.

These are the components that we are going to use for the Hardware: infrared sensor, PIC 16F877A, GSM modem and voice recorder module.

BLOCK DIAGRAM

Final year project briefing was held together with the internship briefing at TTL hall. The attendence was compulsory for all students who are taking final year project this semester. The briefing started at 3.00pm to 5.00pm. The final year project briefing was conducted by FYP's commitees. The briefing was all about:-

- the scheme of work for final year project.

- make a logbook or a blog for final year project and must be updated every week to show project progression.

- every student can claim RM300 per person for the project.

- always meet the supervisor regarding the project.

Our supervisor is Mr Azman from the Electronic Section, level 5.

Back to our project, instead of making the dustbin as an attraction, we add on GSM technology to increse the efficiency of the waste management system.

These are the components that we are going to use for the Hardware: infrared sensor, PIC 16F877A, GSM modem and voice recorder module.

BLOCK DIAGRAM

The figure above is a block diagram for the

deepest bin project using GSM Technology. Infrared sensor will work entirely by

detecting the energy given off by the thrower. When the sensor detects

movement, the voice recorder module will produce sound like a very long fall

followed by a large crash. By placing a simple sound effect it will encourage

people to properly disposing waste. When the trash is full, the infrared sensor

that is also connected to the microcontroller will give command to GSM modem. The

GSM modem will then send a text message to the garbage collector. By implement

this project it will help to increase the efficiency of waste management

system.

***************

Final year project briefing was held together with the internship briefing at TTL hall. The attendence was compulsory for all students who are taking final year project this semester. The briefing started at 3.00pm to 5.00pm. The final year project briefing was conducted by FYP's commitees. The briefing was all about:-

- the scheme of work for final year project.

- make a logbook or a blog for final year project and must be updated every week to show project progression.

- every student can claim RM300 per person for the project.

- always meet the supervisor regarding the project.

Our supervisor is Mr Azman from the Electronic Section, level 5.

Encik Azman Aziz

Friday, 13 September 2013

WEEK 1 (Selection of The Final Year Project & Supervisor)

Last semester (Engineering Design), we chose sir Azman to be our supervisor. He agreed to supervise us. He gave us a project from his previous degree's student. He suggested us to upgrade the project. The name of the project is DB-Con. It was about distribution board.

However, as diploma students, the project was too tough to handle. So we came up with new suggestion to do a smart dustbin. We call it 'The Deepest Bin'.

INTRODUCTION

This project mainly focuses on waste management system. Thus, we've designed a handful of inventions that is a trash can designed to sound like the deepest bin in the world with combination of GSM technology to make waste management system more efficient. To throw rubbish in the bin instead of onto the floor shouldn’t really be so hard. Many people still fail to do so. The best way to change people’s behavior is to make it fun to do. This concept may encourage people to place garbage in a bin. By placing a simple sound effect it completely changed the experience of properly disposing waste. When the trash is full, the indicator that is integrated with sensor and GSM modem that are placed inside the bin will send a text message to the garbage collectors. This system provides an ideal solution to the problems faced by the waste management service and system in various places.

AIM & OBJECTIVES

****************

INTRODUCTION

This project mainly focuses on waste management system. Thus, we've designed a handful of inventions that is a trash can designed to sound like the deepest bin in the world with combination of GSM technology to make waste management system more efficient. To throw rubbish in the bin instead of onto the floor shouldn’t really be so hard. Many people still fail to do so. The best way to change people’s behavior is to make it fun to do. This concept may encourage people to place garbage in a bin. By placing a simple sound effect it completely changed the experience of properly disposing waste. When the trash is full, the indicator that is integrated with sensor and GSM modem that are placed inside the bin will send a text message to the garbage collectors. This system provides an ideal solution to the problems faced by the waste management service and system in various places.

AIM & OBJECTIVES

The

aim of this project is to develop the prototype of The Deepest Bin.

1.

To create a project

that will change people’s behaviour, encourage them to place garbage in a bin

and make it fun to do it by placing a simple sound effect.

2.

To design and develop

tools or components that can increase the efficiency of waste management system

by using GSM technology to send message to the garbage collector when the bin

is full.

Main Cover

BRITISH MALAYSIAN INSTITUTE

FINAL YEAR PROJECT

S2'2013

SUPERVISOR :

Encik Azman Abdul Aziz

PREPARED BY :

Nurul Nabilah Mohd Hazlan

Yasarah Kamarudin

(DET in Telecommunications)

Subscribe to:

Comments (Atom)